Mengxing High Speed Lunch Boxes Vacuum Forming Machine (XC46-71/122A2-WP)

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Basic Info.

Model NO.

XC46-71/122A2-WP

Certification

ISO9001:2008, CE, QS

Trademark

Mengxing

Transport Package

as Standard Exporting Package

Specification

8070*1750*2525mm

Origin

China

HS Code

84774090

XC46-71/122-BWP Automatic High-speed Vacuum Forming Machine

I,Usage

This machine is mainly adapted to a variety of plastic reel sheet vacuum forming various open thin-walled containers for food, souvenirs, travel goods, textiles, decorations, cosmetics, medical supplies, in medicine, children toys, electrical and electronic components, hardware and other goods producing all kinds of packaging products.

II,Available Sheet

1. Starch degradation sheet

2. Optical degradation sheet

3. Green sheet: APET, PETG

4. Various colors sheet: PVC, HIPS, PET, PS, PP, EPS, etc

5. Flocking sheet

III.Features

1. Mechanical, pneumatic and electrical integration. Each action program controlled by the PLC. Touch-screen operation, simple and convenient.

2. Production technology, can be set to automatically shut down or advance warning, with file memory function, can store up to 230 product information and parameters.

3. Frequency sheet feeding, stepless adjustment of length, speed accuracy and stability. (Max.speed 1000mm /s)

4. Temperature control system adopts full computer intelligent automatic compensation control, fast heating (from 0-400 degrees takes 3 minutes), stable (without external voltage impact, temperature fluctuations of not more than 1 degree), low energy consumption (saving about 15%) , heat tiles long life and other advantages.

7. Electric furnace with a bias structure, when the sheet width of less than 580mm, closed electric furnace heat tiles while the entire row can reduce energy consumption by 16%.

8. Furnaces partition a man-machine interface control a digital input, high precision fine-tuning, temperature uniformity, etc..

9. Early feeding with the heating time automatic memory function, since the first edition of the machine can enter the normal working condition.

10. Two steps vacuum,forming mold adjusting twice,shock release; delay vacuum.

11. Products spray silicone devices.

12. Two directions adjustable up and down stroke, in which the upper and lower mold clamping direction of the electric adjustment, can adjust the state in the mold, the lower die height position, and convenient.

13. Electric gate position after adjustment.

14. Upper and lower mold clamping direction readily into the buffer, to improve the speed of the mold, to avoid shock.

15. Upper and lower die sets bushing using mosaic solid lubricating bearings, so that the upper and lower mold under smooth and accurate movement on stage, will help improve the quality of products.

16. Sheet feeding caterpillar width can be synchronous or discrete electric adjustment.

17. Automatic electric furnace removed device is disconnected in the middle of the sheet can be produced at any time without stopping and starting, do not waste sheets.

18. Mechanical reel device, reduce labor intensity.

19. Upper and lower stroke two-way adjustable, the direction in which the upper mold clamping electric adjustment (lower clamping state also available).

20. Double action cutting mechanism plywood, electric slicing methods to meet overcast, sub-version of the male die cutting products of any shape.

21. Cutting machine uses a unique inverted structure can greatly optimize work space. Independent convenience products products stacked car transported to the next process. Movement Guide column, so that products stack neatly.

IV,Technical Parameters

| Parameter | XC46-71/122A-CWP(mode No.) | |

| Available sheet width (mm) | 460-710 | |

| Available sheet thickness (mm) | 0.1-2.0 | |

| Max.dia.of sheet roll (mm) | 600 | |

| Up mold stroke (mm) | 500 | |

| Down mold stroke (mm) | 350 | |

| Max. forming area (mm2) | 680 × 1200 | |

| Max. forming height (mm) | 200 (male mold) | |

| Max. forming depth (mm) | 150 (female mold) | |

| Capacity(times/min) | 4-10 | |

| Products shaping &cooling | Air vent qty. | 4 pcs |

| Spay nozzle qty. | 11 pcs | |

| Gas source | Air supply(m3/min) | ≥ 2 |

| Pressure(Mpa) | 0.8 | |

| Water consumption | 4-5 Cube / Hr | |

| Vacuum pump (external) | Busch R5 0100 | |

| Power supply | three-phase four-wire 380V / 220V 50Hz | |

| Heating power (Kw) | 54 | |

| Max. power of whole machine (Kw) | 62.52 | |

| Dimensions (L × W × H) (mm) | 8070 × 1750 × 2525 | |

| Weight of whole machine(Kgs) | 4900 | |

V,Technical configuration

| HMI 10.4 inches Color | Taiwan Delta |

| PLC 168 | Taiwan Delta |

| Inverter 3.7Kw | Taiwan Delta |

| encoder 1024 | Taiwan Delta |

| pumps | Busch 0100 |

| Cylinders (Up&down molds adopt rough- rod cylinder) | Zhicheng |

| Pneumatic component (waterproof type) | Japan SMC |

| Adjustable spray gun | Meiji |

| Fans (4sets,0.55Kw) | Manda |

| AC contactor | Germany Siemens |

| Thermal relay | Germany Siemens |

| Relay | Omron |

| Heating furnance with 120 pcs of far infrared ceramic heaters,up&down heating furnances, zoning one-one control. | Zoning Adjustment via HMI digital input, accurate and stable. |

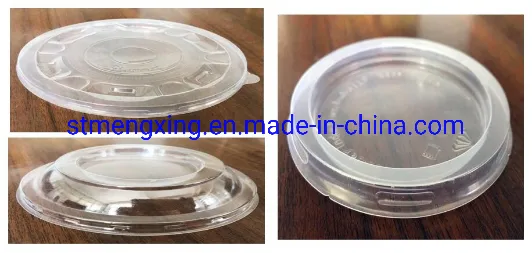

VI,Sample Pictures

VII,Certifications

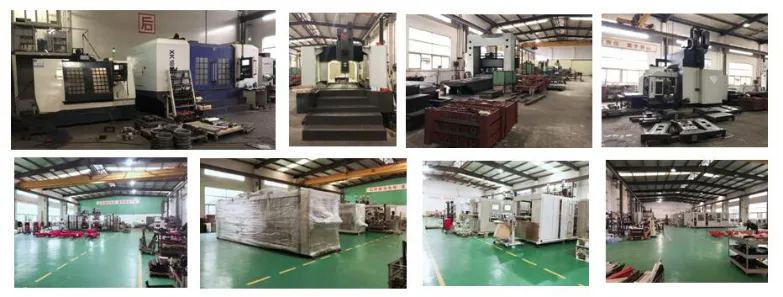

VIII,Workshop Pictures

IX,Package

X,Exhibition

The growth prospect is key to the competitiveness of the product. The servo motor adopted is super powerful.

Years of production and application have shown its sound prospects. The servo motor adopted is super powerful.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Quick Links

Products

Contact Us

Tel: +86-754-88228822

Fax: +86-754-88584033

E-mail: mx1@stmengxing.cn

Address: Block 11, Jinyuan Industrial District, Chaoshan Rd. West, Shantou, Guangdong China

E-mail: mx1@stmengxing.cn

Address: Block 11, Jinyuan Industrial District, Chaoshan Rd. West, Shantou, Guangdong China