Disposable Food Dishes Machine Supplier Fully Automatic Plastic Blister Thermoforming Machine Plastic Tray Vacuum Forming Machine

Basic Info.

Disposable Food Dishes Machine Supplier Fully Automatic Plastic Blister Thermoforming Machine Plastic Tray Vacuum Forming Machine

With food forming machines for meat, poultry, fish and alternative proteins, Stmengxing can provide a solution to meet your capacity needs. The food forming machine is a hydraulic microprocessor-controlled unit that combines weight control, minimal leakage and fast changeover with mobility; it can be easily transported to the wash down department or other areas of the factory. Shapers run beef, pork, poultry, fish, vegetables and cheese. Are you looking for an affordable food forming machine? You have come to the right site! On this page, you can find our food forming machine. The Stmengxing food forming machine series is the perfect solution for your food forming and portioning requirements. Customized sizes and specifications according to your drawings or samples. Our food forming machine supplier can manufacture food forming machines according to your requirement, specification, size and quality. In general, "moulding machine" refers to secondary metalworking machines such as metalworking machines and metal forming machines (machines that cut with tools) other than machine tools.

This machine is mainly adapted to a variety of plastic reel sheet vacuum forming various open thin-walled containers for food, souvenirs, travel goods, textiles, decorations, cosmetics, medical supplies, Western medicine, children's toys, electrical and electronic components, hardware and other goods producing all kinds of packaging products.

II, Available sheet

1. Starch degradation sheet

2. Optical degradation sheet

3. Green sheet: APET, PETG

4. Various colours sheet: PVC, HIPS, PET, PS, PP, EPS, etc.

III, Features

01. mechanical, pneumatic, electrical integration. Each action program is controlled by the PLC. Touch-screen operation is simple and convenient.

02. Frequency sheet feeding, step-less adjustment of the length, accurate and stable speed. (Max.Speed:1000mm/s)

03. Electric furnace temperature control system is fully computerized intelligent automatic compensation control, partitioning a controlled man-machine interface of a digital input, with high precision fine-tuning, temperature uniformity, fast heating (from 0-400 degrees 3 minutes), stable ( influence from external voltage, temperature fluctuations of not more than 1 degree), low energy consumption (15% saving), hearth advantages of long life.

04. Double electric oven.

05. Electric furnace with a bias structure, when the sheet width of less than 580mm, closed electric furnace side of the row of brick fever can reduce energy consumption by 16%.

06. Early feeding with the heating time automatic memory function, since the first version of the machine can enter the normal working condition.

07. Vacuum in two steps, forming mold adjusted twice, shock release, delay vacuum.

08. Up and down mould stroke can be adjusted in two directions. The closing method of up mold adopts electric adjustment. The height of up&down mold can be adjusted when closing mold, convenient and fast.

09.Electric adjust the position of the rear upper flashboard.

10. The down mold clamping direction readily into the buffer, to improve the speed of mold clamping, to avoid shock.

11. The guide sleeve of up&down mold plates adopts insert solid lubrication bearing, which makes them move smoothly and accurately, and is helpful to improve the products quality.

12. With an electric furnace automatic removal device, in the middle of production,it doesn't need to disconnect the sheet.It can stop or start up at any time, which do not waste sheet.

13. Mechanical reel device, reduce labour intensity.

14 Movement guide column, so that products stack neatly.

15. 10.4-inch colour touch screen, optimized operating environment.

16. Front &rear upper flashboards are made of aluminium alloy material, anti-rust and improve product quality.

IV, Technical parameters

| Parameter | XC46-71/122-BWP(mode No.) | |

| Available sheet width (mm) | 460-710 | |

| Available sheet thickness (mm) | 0.1-1.2 | |

| Max.dia.of sheet roll (mm) | 600 | |

| Up mold stroke (mm) | 400 | |

| Down mould stroke (mm) | 300 | |

| Max. forming area (mm2) | 680 × 1200 | |

| Max. forming height (mm) | 200 | |

| Max. forming depth (mm) | 150 | |

| Capacity (Cycle / min) | 4-10 | |

| Product Shaping&Cooling | Air vent qty. | 4 pcs |

| Spray nozzle qty. | 8 pcs | |

| Gas Source (outlay) | Air supply(m3/min) | ≥ 2 |

| Pressure(Mpa) | 0.8 | |

| Water consumption | 4-5 Cube / Hour | |

| Vacuum pump (Outlay) | Busch R5 0100 | |

| Power supply | 3-phase 4-wire 380V/220V 50Hz | |

| Heating power(Kw) | 30 | |

| Feeding motor power (Kw) | 2.2 | |

| Max.power of whole machine(Kw) | 37 | |

| Dimensions (L × W × H) (mm) | 8070 × 1656 × 2425 | |

| Total weight of whole machine (Kgs) | 4600 | |

V,Technical configuration

| Programmable logic controller (PLC) | Taiwan Delta |

| 10.4 inches color touch screen | Taiwan Delta |

| Drive inverter | Taiwan Delta |

| Feeding motor (3Kw) | China |

| Encoder | Japan |

| Heater (59pcs) | China |

| Heater with sensor (1pc) | Germany |

| Solid-state regulator | China |

| AC contactor | Germany Siemens |

| Thermal relay | Germany Siemens |

| Intermediate relay | Germany Weidmuller |

| Vacuum pump | Busch R5 0100 |

| Pneumatic components | Korea Sanwo&Japan SMC |

| Cylinder | China |

| Air sprayer (8pcs) | Meiji |

| Fan (4 × 0.37 kw) | Manda |

VI,Sample Pictures

VII,Certifications

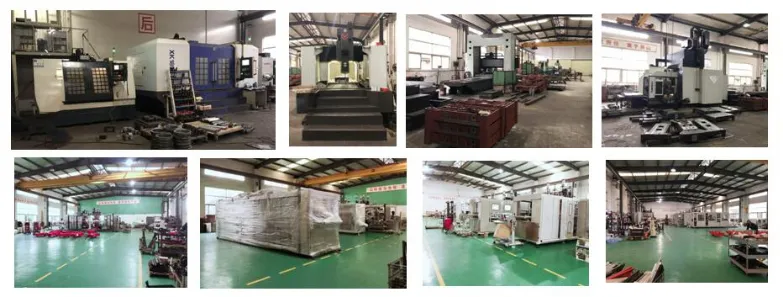

VIII,Workshop Pictures

IX,Package

X,Exhibition

Quick Links

Products

Contact Us

E-mail: mx1@stmengxing.cn

Address: Block 11, Jinyuan Industrial District, Chaoshan Rd. West, Shantou, Guangdong China