Lxc 85-135/190-W New Full Automatic Filling Material Cooling Tower

Basic Info.

Water Cooling Tower Filler Forming Machine

I,Usage

This cooling tower fill is widely used for making vacuum formed products like cooling tower fills from PVC, PS and so on.

II,Operation Principle

Operation processes: The heated and soften plastic sheet are being vacuum formed in the mold in order to get the various finished products. The operation processes are: sheet-feeding-heated-forming-side trimming- crosscut.

III,Structure feature

01. The cooling tower fill is combined with pneumatic , mechanical and electricity driving, adpot PLC control . It can achieve sheet feeding , heating , forming , side trimming , crosscut into continuous job .

All working action can adjust uder non-stop production . It's convenient and high capacity , easy for operation .

02. The working method can crosscut by different pattern of fill .

03. Servo Motor feeding , Feeding Length stepless adjustabe , precision and reliable.

04. Cutting Unit with Servo Motor Driving , Electrical & Pneumatic adjustable by different length crosscut ( the length must be longer than each forming mold length ) .

05. Forming area is big and easy for mold installation & replace.

06. Cylinder Roll Sheet Loading , Feeding Chain manual adjust.

07. Upper , Lower mold stroke limited , Up mold descend motor adjust.

08. Forming area double adjustable , can save the sheet material .

09. Back acting plate adopt double cylinder method , motor setting position .

10. Two step of Vacuum .

11. Fan Blowing , Air Spray Cooling Device .

12. Heater adopt individual heating temperature control . ( Point to Point )

13. Advance sheet feeding , heating parameter can automatic adjust.

IV,Technical Parameters

Sheet size | width 700-1350mm, thickness 0.12-1.2mm |

Max. sheet sending length | 1900mm |

Max. forming area | 1320×1880mm |

Capacity | 4-10cycles/min |

Power usage | 415V(3 phases 4 lines), max. 112.93Kw total |

Air consumption | ≥2 m³/min. (prepare by client). |

Operation air pressure | 0.7Mpa(air source 0.8-1mpa). |

Dimension(L×W×H) | 8070×3920×2575mm |

Weight | about 3200kgs |

V,Sample Pictures

VI,Mold Pictures

VII,Certifications

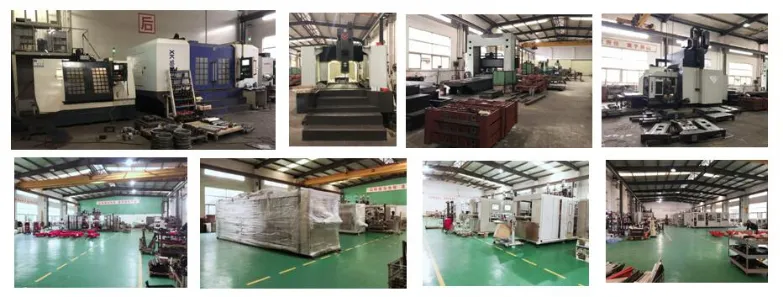

VIII,Workshop Pictures

IX,Package

X,Exhibition

Quick Links

Products

Contact Us

E-mail: mx1@stmengxing.cn

Address: Block 11, Jinyuan Industrial District, Chaoshan Rd. West, Shantou, Guangdong China