Cooling Tower Fills Forming Machine

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Basic Info.

Model NO.

LXC70-135/190-BWF

Certification

ISO9001:2008, CE

Trademark

Mengxing

Transport Package

as Standard Exporting Packaging

Origin

China

HS Code

84774090

I,Usage

This vacuum forming machine is widely used for making vacuum formed products like cooling tower fills from PVC, PS, PP, EPS, PET, Bio-degradable material, APET, PETG and so on.

II,Operation Principle

Operation processes: The heated and soften plastic sheet are being vacuum formed in the mold in order to get the various finished products. The operation processes are: sheet-feeding-heated-forming-side trimming- crosscut.

III,Structure feature

01. The machine is combined with pneumatic , mechanical and electricity driving, adopt PLC control . It can achieve sheet feeding , heating , forming , side trimming , crosscut into continuous job .

All working action can adjust uder non-stop production . It's convenient and high capacity , easy for operation .

02. The working method can crosscut by different pattern of fill .

03. Servo motor feeding , feeding length stepless adjustabe , precision and reliable.

04. Cutting unit with servo motor driving , electrical & pneumatic adjustable by different length crosscut ( the length must be longer than each forming mold length ) .

05. Forming area is big and easy for mold installation & replace.

06. Cylinder roll sheet loading , feeding chain manual adjust.

07. Upper , lower mold stroke limited , up mold descend motor adjust.

08. Forming area double adjustable , can save the sheet material .

09. Back acting plate adopt double cylinder method , motor setting position .

10.Vacuum in two steps.

11. Fan blowing , air spray cooling device .

12. Heater adopt individual heating temperature control . ( Point to Point )

13. Advance sheet feeding , heating parameter can automatic adjust.

IV,Technical Parameters

| Parameter | XC100-130/125-BWF (mode No.) | |

| Suitable sheet width(mm) | 1000-1300 | |

| Sheet thickness(mm) | 0.3-1 | |

| Max.dia. of sheet roll (mm) | 600 | |

| Up mold stroke(mm) | 300 | |

| Down mold stroke(mm) | 250 | |

| Max. forming area(mm2) | 1200×1200 | |

| Max. forming height(mm) | 120 | |

| Max. forming depth(mm) | 100 | |

| Capacity (cycle/min) | 4-8 | |

| Product Shaping& Cooling | Air vent qty. | 7PCS |

| Air sprayer qty. | 16PCS | |

| Gas source (outlay) | Air supply (m3/min) | ≥3 |

| Pressure(MPa) | 0.8 | |

| Water consumption | 4-5 Cube/Hour | |

| Vacuum pump ( Outlay ) | Busch R5 0100 | |

| Power supply | 3-phase 4-wire 415V/ 220V 50Hz | |

| Heating power(Kw) | 59.4 | |

| Feeding motor power(Kw) | 3.0 | |

| Power of whole machine(Kw) | 68.6 | |

| Dimension(L×W×H)(mm) | 9600×3400×2500 | |

| Weight(Kgs) | 7500 | |

V,Technical configuration

| PLC | Taiwan Delta |

| Touch screen monitor ( 10.4″inch /Color ) | Taiwan Delta |

| Feeding motor(3.0kw) | Taiwan Delta |

| Heater with probe(1pcs) | Germany |

| Heater(99pcs) | China |

| Solid voltage regulator | China |

| Contactor | Germany Siemens |

| Thermo relay | Germany Siemens |

| Relay | Japan Omron |

| Vacuum pump(2 set) | Busch R5 0100 |

| Pneumatic component | Japan SMC |

| Cylinder | China |

| Air sprayer(8pcs) | Meiji |

| Fan blower(4×0.55 Kw ) | Manda |

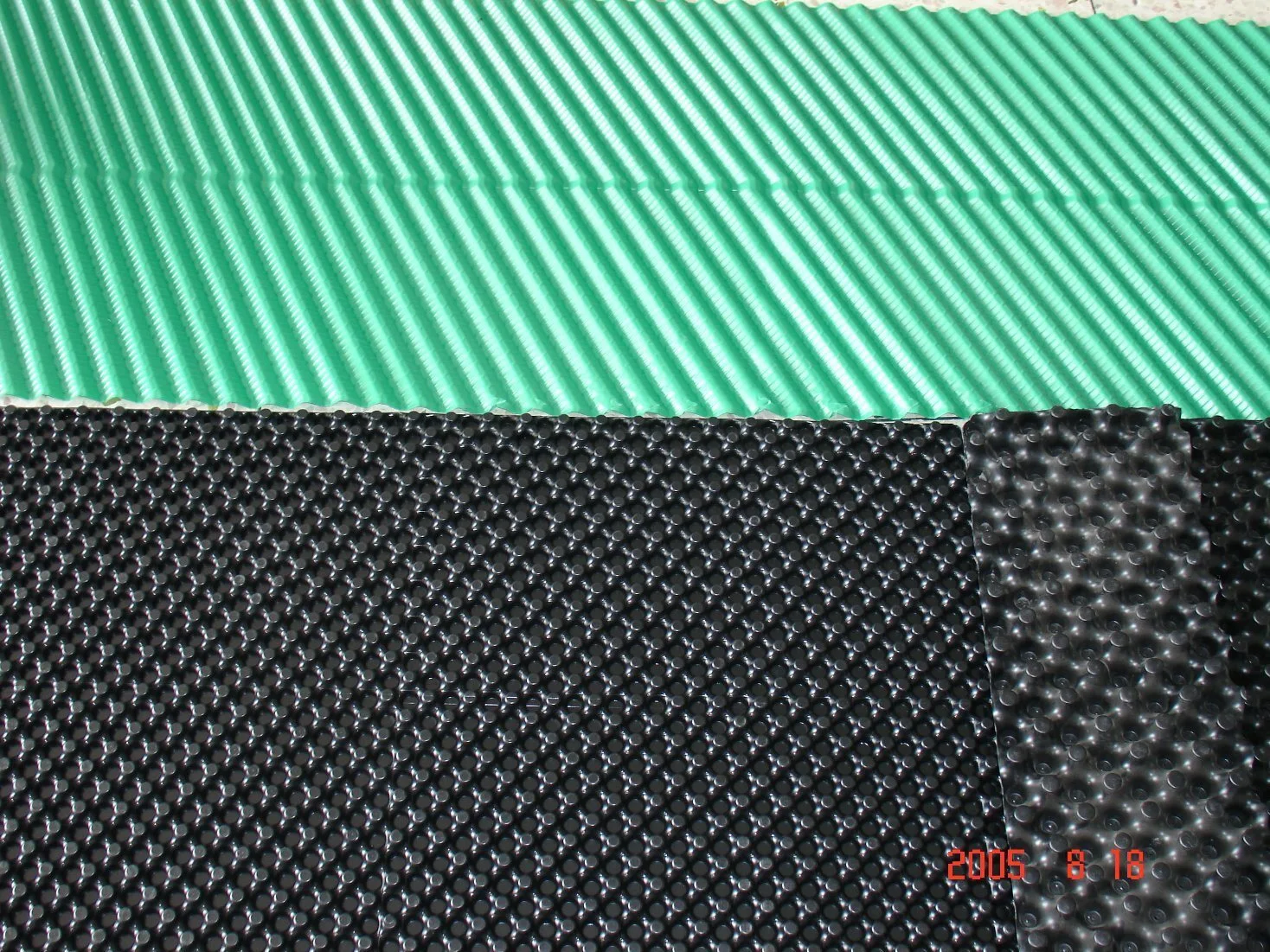

VI,Sample Pictures

VII,Mold Pictures

VIII,Certifications

IX,Workshop Pictures

X,Package

XI,Exhibition

With promising development prospects in the field, the product is widely used. The product has a fast operation speed.

The growth prospect of the product is fueled by an increased demand from customers. The product has a fast operation speed.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Quick Links

Products

Contact Us

Tel: +86-754-88228822

Fax: +86-754-88584033

E-mail: mx1@stmengxing.cn

Address: Block 11, Jinyuan Industrial District, Chaoshan Rd. West, Shantou, Guangdong China

E-mail: mx1@stmengxing.cn

Address: Block 11, Jinyuan Industrial District, Chaoshan Rd. West, Shantou, Guangdong China