Cooling Tower Fill Forming Machine (LXC70-135/190-BWF)

Basic Info.

LXC70-135/190-BWF Cooling Tower Fill Forming Machine

I,Usage

This vacuum forming machine is widely used for making vacuum formed products like cooling tower fills from PVC, PS, PP, EPS, PET, Bio-degradable material, APET, PETG and so on.

II,Operation Principle

Operation processes: The heated and soften plastic sheet are being vacuum formed in the mold in order to get the various finished products. The operation processes are: sheet-feeding-heated-forming-side trimming- crosscut.

III,Structure feature

01. The machine is combined with pneumatic , mechanical and electricity driving, adopt PLC control . It can achieve sheet feeding , heating , forming , side trimming , crosscut into continuous job .

All working action can adjust uder non-stop production . It's convenient and high capacity , easy for operation .

02. The working method can crosscut by different pattern of fill .

03. Servo motor feeding , feeding length stepless adjustabe , precision and reliable.

04. Cutting unit with servo motor driving , electrical & pneumatic adjustable by different length crosscut ( the length must be longer than each forming mold length ) .

05. Forming area is big and easy for mold installation & replace.

06. Cylinder roll sheet loading , feeding chain manual adjust.

07. Upper , lower mold stroke limited , up mold descend motor adjust.

08. Forming area double adjustable , can save the sheet material .

09. Back acting plate adopt double cylinder method , motor setting position .

10.Vacuum in two steps.

11. Fan blowing , air spray cooling device .

12. Heater adopt individual heating temperature control . ( Point to Point )

13. Advance sheet feeding , heating parameter can automatic adjust.

IV,Technical Parameters

Sheet size | width 700-1350mm, thickness 0.12-1.2mm |

Max. sheet sending length | 1900mm |

Max. forming area | 1320×1880mm |

Capacity | 4-10cycles/min |

Power usage | 415V(3 phases 4 lines), max. 112.93Kw total |

Air consumption | ≥2 m³/min. (prepare by client). |

Operation air pressure | 0.7Mpa(air source 0.8-1mpa). |

Dimension(L×W×H) | 8070×3920×2575mm |

Weight | about 4500kgs |

V,Technical Components

| PLC | Taiwan Delta |

| Touch Screen Monitor ( 7″inch /Color ) | Taiwan Delta |

| Feeding Servo Motor(3.0kw) | Taiwan Delta |

| Servo Motor of cutting unit (0.75kw) | Taiwan Delta |

| Heater (164 PCS) | CHINA |

| Solid Voltage Regulator | CHINA |

| Contactor | Germany Siemens |

| Thermo Relay | Germany Siemens |

| Relay | JAPAN Omron |

| Vacuum Pump (2 sets) | Busch R5 0100 |

| Pneumatic | SMC |

| Cylinder | CHINA |

| Air Sprayer | Meiji |

| Fan Blower (7×0.55 kw ) | Manda |

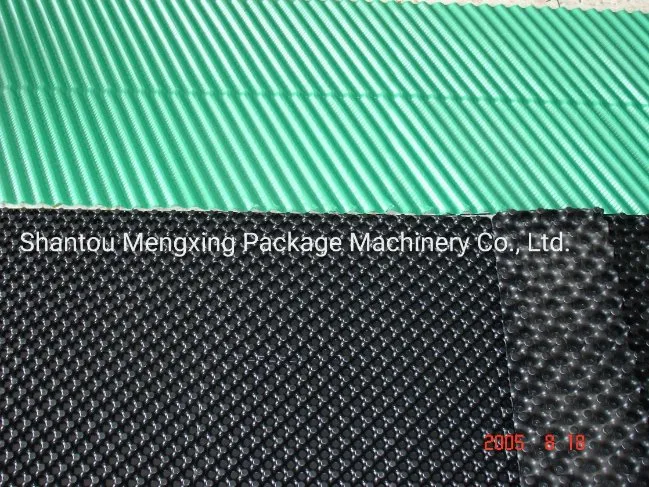

VI,Sample Picture

VII,Certifications

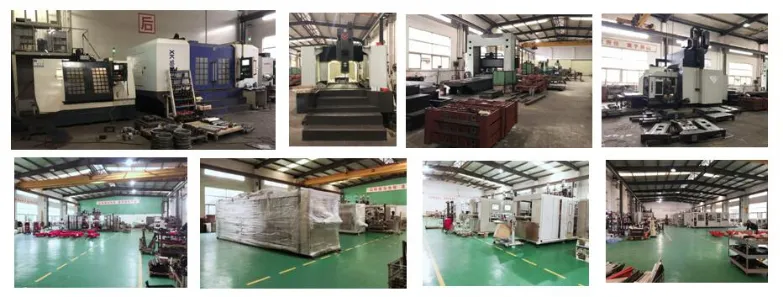

VIII,Workshop Pictures

IX,Package

X,Exhibition

Quick Links

Products

Contact Us

E-mail: mx1@stmengxing.cn

Address: Block 11, Jinyuan Industrial District, Chaoshan Rd. West, Shantou, Guangdong China