Plastic Molding Equipment Mengxing

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Basic Info.

Model NO.

XCH130/110/13.5

Trademark

MengXing

Specification

4200 * 2410* 2900mm

Origin

China

HS Code

84775900

I,Work principle

Using the thermoplastic sheet is heated and softened in the mold for vacuum molding, become necessary products. Their work is the clip - heating - forming - products.

II,Features

01. Mechanical, pneumatic, electrical integration. Each action program controlled by the PLC. Touch-screen operation, simple and convenient.

02. Loading easier, less scrap molding material savings.

03. Heater motor, frequency control, high-speed accurate and stable.

04. Electric furnace temperature control system is fully computerized intelligent automatic compensation control, partitioning a controlled man-machine interface of a digital input, with high precision fine-tuning, temperature uniformity, fast heating (just five minutes from 0-400 degrees), stable ( influence from external voltage, temperature fluctuations of not more than 1 degree), low energy consumption (saving about 15%), long life plate stove, electric bricks etc. automatically detected.

05. Suitable convex molding, molding height, stable product quality.

06. The mold seat with electric limit adjustment, adjust quickly and easily.

07. Device is equipped with air-cooling system that allows products to cool faster and better styling.

08. Production counts, or can be set to automatically shut down ahead of the police, with file memory function, can store up to 230 product parameter data

09. The die table using mosaic lubricated bearings, freedom of movement and accurate.

10. Die clip structure movements and synchronized by the rack and pinion structure linkage, the lifting synchronization, extending cylinder life

11. Operating side using safety grating devices to ensure the safety of the operator misuse.

III,Technical parameters

| Parameter | XCH130/110/13.5(mode No.) | |

| Max. forming area (mm2) | 1300mm*1100mm | |

| Min.forming area (mm2) | 1200mm * 1000mm | |

| Sheet specifications (Max.) | 1370mm * 1170mm | |

| Thickness of sheet applied | 0.8-3mm | |

| Max. molding height | 135mm | |

| Capacity | 1-3 (times/min) | |

| Gas source | Air consumption (m3/min) | ≥ 2 |

| Pressure | 0.6Mpa(inlet 0.8-1Mpa) | |

| Vacuum pump (Outlay) | Busch R5 0100 | |

| Power | three-phase four-wire 380V / 220V 50Hz | |

| General power | 64KW | |

| Dimensions ( L × W × H) (mm) | 4200 * 2410 * 2900 | |

| Total weight (Kgs) | 4000 | |

IV,Technical configuration

| Programmable logic controller (PLC) | Taiwan Delta |

| Touch screen monitor (10.4 "inch / Color) | Taiwan Delta |

| Inverter | Taiwan Delta |

| Feeding motor | China |

| Heater (99pcs) | China |

| Solid state relay AC contactor | Germany Siemens |

| Thermo relay | Japan Omron |

| Vacuum pump | Busch R5 0100 |

| pneumatic components | South Korea |

| Cylinder | China |

| Fan blower | China |

V,Installation Instructions

1. The machine should be installed in a dry, clean shop floor. And leave some aside installation location of the active working distance gas, electricity, refer to the machine diagram of a flat position.

2. After removing the packaging machine, placed on the ground level of the firm can use. Its area, see the appearance of space dimensions Figure II.

3. Were connected to a source of water and gas supply, and connect the ground wire.

4. Check heater heating elements are intact (Ruoyin shipping damage should be replaced).

5. All lubrication points should be added to lubricants. Vacuum pumps, air source FRL oil level should come on to the line. The watershed of the filter device slop put the net.

6. Check the vacuum pump motor, cooling fan rotation is correct (after power test, which if not properly swap two wires can).

7. Supply part of the user's machine to install their own gas purification equipment, in order to ensure increased service life of pneumatic components. Please refer to the pneumatic equipment clean air system flow chart diagram III.

8. External power cable with double insulated copper wire 4, each section is not less than 16mm2.

VI,Sample Picture

VII,Certifications

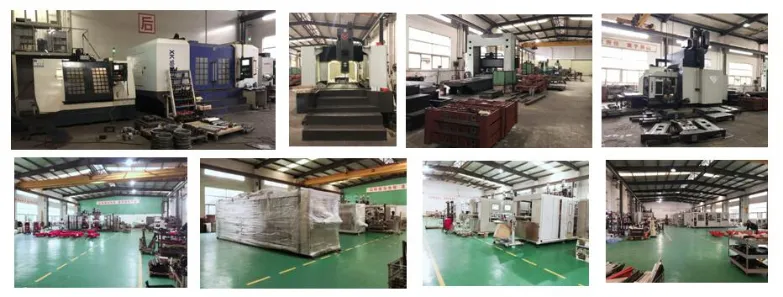

VIII,Workshop Pictures

IX,Package

X,Exhibition

It is of great importance for Mengxing to provide exquisite customer service. Installed with a highly advanced die change equipment, it features high work efficiency.

We believe that there are good prospects for this product. Installed with a highly advanced die change equipment, it features high work efficiency.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Quick Links

Products

Contact Us

Tel: +86-754-88228822

Fax: +86-754-88584033

E-mail: mx1@stmengxing.cn

Address: Block 11, Jinyuan Industrial District, Chaoshan Rd. West, Shantou, Guangdong China

E-mail: mx1@stmengxing.cn

Address: Block 11, Jinyuan Industrial District, Chaoshan Rd. West, Shantou, Guangdong China