Introduces a thick piece of vacuum molding machine working principle of the equipment

by:Mengxing

2020-12-29

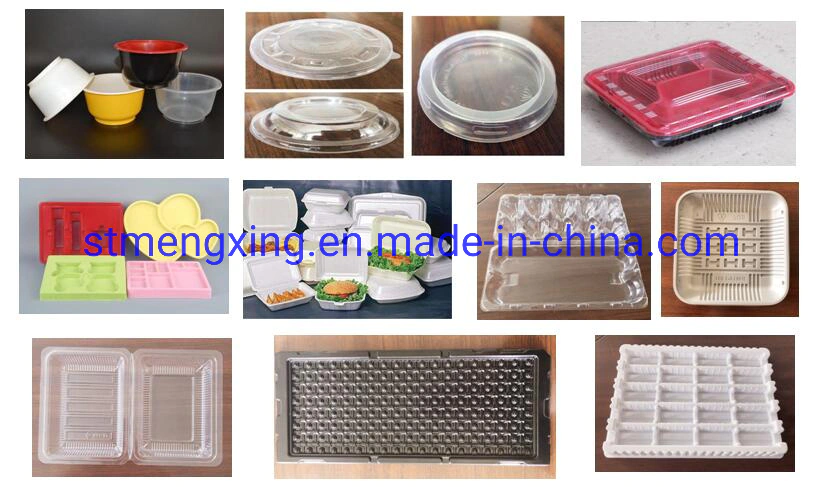

Thick slices vacuum forming machine is the plastic sheet as raw material, through vacuum molding vacuum molding process for making plastic parts of key process equipment, it by thermoplastic plastic sheet as raw material, through the oven heated to a softening temperature, and then through the plastic sheet between the vacuum forming mold and vacuum negative pressure effect, make in the state of the thermoplastic plastic plate adsorption cooling molding again on the surface of the vacuum forming mold work.

Thick slices of vacuum forming machine principle is as follows: thick slices vacuum forming similar to chip vacuum forming principle, is to locate a good plank through oven heated to softening state, the vacuum forming mold with form around confined Spaces and sucking air in the cavity moment, this plate in mold surface, after heating process of obtained products.

Vacuum forming is a process of circulation, each cycle mainly includes: material -

Heating softening -

Blow pre-drawn -

Vacuum forming -

Cooling stereotypes -

Demoulding to take the back analysis.

After take out the plastic sheet placed (again

Can be received or automatic)

For the next cycle.

Custom message