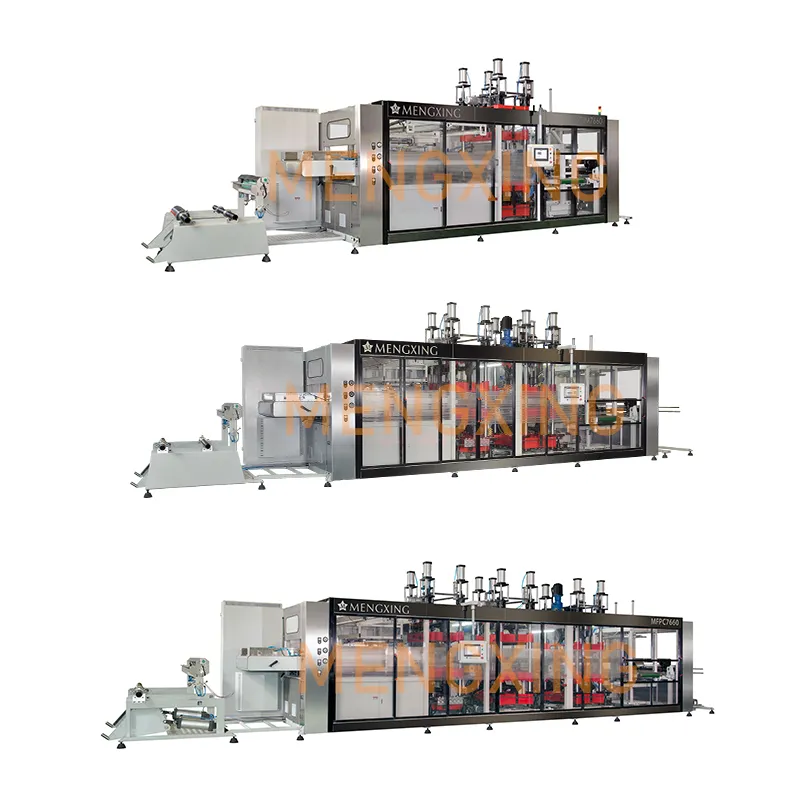

Hot Thermoforming Machine Automatic Fast Food Pan Disposable Box Pressure Vacuum Forming Machine Tray Making Machine

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Basic Info.

Model NO.

Presure Vacuum Machine

HS Code

84774090

Thermoforming Machine Fast Food Pan Disposable Box Pressure Vacuum Machine

![Hot Thermoforming Machine Automatic Fast Food Pan Disposable Box Pressure Vacuum Forming Machine Tray Making Machine]()

MFPC7660 4 Stations Pressure & Vacuum Forming Machine

I,Usage

This machine is designed for producing all size packaging containers, in open-type with thin wall, by using roll-sheet, under high-speed vacuum suction-forming processing. The products made by this machine can be used for the package of foods, tourist-goods, textile, medical, toy, cosmetic, electrical elements and daily used hard-ware, etc.

Suitable Sheet

Starch-deposit sheets, light-deposit sheet, environment sheet, APET, PETG. PVC, HIPS, PET, PS, OPS,etc.

II,Structure Feature

1. Mechanical, pneumatic and electrical combination, all working actions are controlled by PLC. Touch screen makes the operation convenient and easy.

2. Pressure And/Or Vacuum forming.

3. Up and down mold forming method.

4. Servo motor feeding, feeding length can be step-less adjusted. High speed and accurate.

5. Upper & lower heater, three sections heating

6. Heater with intellectual temperature control system, automatic supply the heating individual heater control. Fast heating(3 min from 0-400 degree), it won't be effected by outer voltage.

7. Forming,Punching,cutting unit mold open and close controlled by servo motor, products automatically count.

8. Data memorization function can store 120 set of running data.

III,Technical Parameter

IV,Technical Configuration

![Hot Thermoforming Machine Automatic Fast Food Pan Disposable Box Pressure Vacuum Forming Machine Tray Making Machine]()

![Hot Thermoforming Machine Automatic Fast Food Pan Disposable Box Pressure Vacuum Forming Machine Tray Making Machine]()

![Hot Thermoforming Machine Automatic Fast Food Pan Disposable Box Pressure Vacuum Forming Machine Tray Making Machine]()

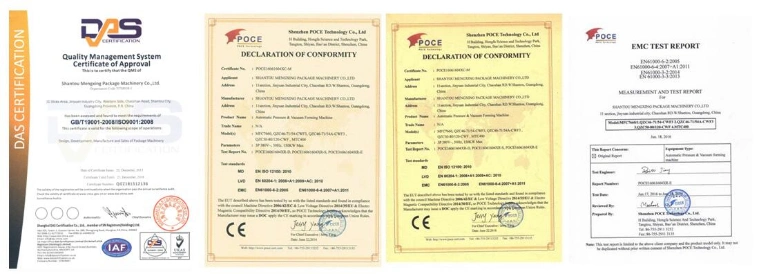

VII,Certifications

![Mengxing Vacuum Forming Machine (XC46-71/122A-BWP)]()

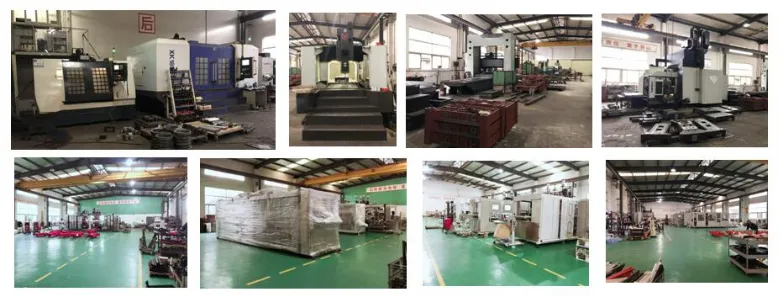

VIII,Workshop Pictures

![Mengxing Vacuum Forming Machine (XC46-71/122A-BWP)]()

IX,Package

![Hot Thermoforming Machine Automatic Fast Food Pan Disposable Box Pressure Vacuum Forming Machine Tray Making Machine]()

X,Exhibition

![Hot Thermoforming Machine Automatic Fast Food Pan Disposable Box Pressure Vacuum Forming Machine Tray Making Machine]()

MFPC7660 4 Stations Pressure & Vacuum Forming Machine

I,Usage

This machine is designed for producing all size packaging containers, in open-type with thin wall, by using roll-sheet, under high-speed vacuum suction-forming processing. The products made by this machine can be used for the package of foods, tourist-goods, textile, medical, toy, cosmetic, electrical elements and daily used hard-ware, etc.

Suitable Sheet

Starch-deposit sheets, light-deposit sheet, environment sheet, APET, PETG. PVC, HIPS, PET, PS, OPS,etc.

II,Structure Feature

1. Mechanical, pneumatic and electrical combination, all working actions are controlled by PLC. Touch screen makes the operation convenient and easy.

2. Pressure And/Or Vacuum forming.

3. Up and down mold forming method.

4. Servo motor feeding, feeding length can be step-less adjusted. High speed and accurate.

5. Upper & lower heater, three sections heating

6. Heater with intellectual temperature control system, automatic supply the heating individual heater control. Fast heating(3 min from 0-400 degree), it won't be effected by outer voltage.

7. Forming,Punching,cutting unit mold open and close controlled by servo motor, products automatically count.

8. Data memorization function can store 120 set of running data.

9. Products stacked downward.

10. Feeding width can be synchronously or independently adjusted in electrical way.

10. Feeding width can be synchronously or independently adjusted in electrical way.

11. Heater will automatically push-out when the sheet is over heated.

12. Auto roll sheet loading, Quick mold change system, reduce the working load.

III,Technical Parameter

| Sheet width (mm) | 500-800 | |

| Sheet thickness (mm) | 0.1-1.5 | |

| Max roll sheet diameter (mm) | 800 | |

| Forming mold stroke (mm) | (Up ) 140,(down) 140 | |

| Mold clamping force/Punching force(ton) | 45 | |

| Max forming area (mm2) | 760×600 | |

| Min forming area (mm2) | 500×330 | |

| Forming mold width (mm) | 500-760 | |

| Forming mold length (mm) | 460-600 | |

| Max forming depth/height (mm) | 120/ 70 | |

| Cutting mold stroke(mm) | (up)80,(down)140 | |

| Max cutting area (mm2) | 760×600 | |

| Cutting force(ton) | 60 | |

| Cycle (time/ min) | Max30 | |

| Cooling | Water cooling | |

| Air supply | volume (m3/ min) | ≥2 |

| Air pressure (MPa) | 0.8 | |

| Vacuum pump | Busch R5 0100 | |

| Power supply | 3 phase 4 line 380V50Hz | |

| Heater power (kw) | 120 | |

| Max general power (kw) | 160 | |

| Dimension (L×W×H) (mm) | 14000×3300×3500 | |

| Weight ( T ) | ≈18 | |

IV,Technical Configuration

| PLC | Taiwan Delta |

| Touch Screen Monitor ( 10.4″inch /Color ) | Taiwan Delta |

| Feeding servo motor(5kw) | Taiwan Delta |

| Forming up/down mold servo motor(4.5kw) | Taiwan Delta |

| Punching up/down mold servo motor(4.5kw) | Taiwan Delta |

| Cutting up/down mold servo motor(5+4.5kw/4.5kw) | Taiwan Delta |

| Heater(196 pcs) | Germany Elstein |

| Contactor | Germany Siemens |

| Thermo Relay | Germany Siemens |

| Relay | Germany Weidmuller |

| Vacuum Pump | Germany Busch |

| Electronic pressure sensor | Taiwan Delta |

| Pneumatic | JAPAN SMC |

| Cylinder | JAPAN SMC & Taiwan Airtac |

VII,Certifications

VIII,Workshop Pictures

IX,Package

X,Exhibition

Supported by ingenious team, Mengxing has highly recommended service team.

vacuum forming machine is widely appraised for its stable quality.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Quick Links

Products

Contact Us

Tel: +86-754-88228822

Fax: +86-754-88584033

E-mail: mx1@stmengxing.cn

Address: Block 11, Jinyuan Industrial District, Chaoshan Rd. West, Shantou, Guangdong China

E-mail: mx1@stmengxing.cn

Address: Block 11, Jinyuan Industrial District, Chaoshan Rd. West, Shantou, Guangdong China