Full-Auto Forming, Cutting&Stacking Production Line

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Basic Info.

Model NO.

QZC50-80/120-CWF&MT400

HS Code

84774090

Full-auto Forming,Cutting&Stacking Production Line

![Full-Auto Forming, Cutting&Stacking Production Line]()

QZC50-80/120-CWF Automatic Pressure & Vacuum Forming Macine

I,Features

01. Mechanical, pneumatic and electrical combination. All working actions are controlled by PLC with touch screen, very easy and convenient in operation.

02. Servo motor feeding, feeding length is steplessly adjusted, which is fast and accurate. (Max.speed:1000mm/s)

03 Heater with intellectual temperature control system an automatically supply the heating individual heater control, which is convenient for temperature's uniformity.This system has advantages of easy operating, convenient, fast heating(only 5 min from 0-400degree), stable(won't be effected by outter voltage,temperature fluctuation is less than 1 degree),saving energy(about 15%) and long life of the usage of firebacks.

04. ]Double heater(up and down) with sheet pro-heat equipment.

05. With sheet drooping detection and protection equipment.

06. Feeing sheet ahead of time. The machine has the automatically memory function of heating time to make the machine access the normal working situation at the very beginning.

07. Mould delay.

08. The forming up and down mould use the pneumatic double elbow system and the guide bushing uses inlay bearing with solid lubricant(JFB) to make the up and down mould work stably and accurately. The mould clamping force is large and good for improving the quality of the products.

09. Heater automatically push-out function make it possible to pur off and on the machine without cutting the sheet during the production procedure, then saving the sheet.

10 . The up and down moulds use electrically adjusting system, is high speed and convenient.

11. With quickly change mould equipment, pneumatically clamping.

12. The up mould equips assistant stretching air cylinder and the down mould equips assistant demoulding air cylinder.

13. The forming has several type to be chose---vacuum forming, pressure forming, vacuum and pressure forming.

14. Automatically roll sheet loading, ease the labour intensity.

II,Technical Parameter

| Parameter | QZC50-80/120-CWF (mode No.) | |

| Available Sheet(mm) | 500-760 | |

| Sheet thickness(mm) | 0.3-1.5 | |

| Max.dia. of sheet roll(mm) | 600 | |

| Up mould stroke(mm) | 130 | |

| Down mould stroke(mm) | 130 | |

| Max.forming area(mm2) | 720×750 | |

| Max.forming height(mm) | 70 | |

| Max.forming depth(mm) | 100 | |

| Capacity (Cycle/min) | 6-16 | |

| Gas Source | Air supply (m3/min) | ≥3 |

| Pressure(MPa) | 0.8 | |

| Water consumption | 4-5 Cube/Hour | |

| Vacuum pump | Busch R5 0100 | |

| Power | 380V/ 220V 50Hz | |

| Heater power (Kw) | 86.4 | |

| Motor power (Kw) | 8 | |

| General power (Kw) | 96 | |

| Dimension (L×W×H)(mm) | About 7500×1800×2300 | |

| Weight (Kgs) | About 7800 | |

III,Technical Equipments

| PLC | Taiwan Delta |

| Touch screen monitor ( 10.4″inch /Color ) | Taiwan Delta |

| Feeding motor(4.5kw) | Taiwan Delta |

| Heater | Germany |

| Solid voltage regulator | China |

| Contactor | Germany Siemens |

| Thermo relay | Germany Siemens |

| Relay | Germany Weidmuller |

| Vacuum pump | Busch R5 0100 |

| Pneumatic | Japan SMC |

| Cylinder | China |

MTC 400 Automatic Cutting &Stacking Machine

I,Features

01. This machine mechanical, pneumatic, electrical integration. Each action program controlled by the PLC. Touch-screen operation, simple and convenient.

02. servo motors sheet feeding, step-less adjustment of length, speed accuracy and stability.

03. Adapt with ordinary plastic machine, vacuum forming machine connections are trimmed.

04. Cutting using laser cutter mold, the lower the cost.

05. Using die cutting technology shift, little can be achieved without cutting plastic products, in line with most of the food packaging requirements.

06. Cutting clamping down with full servo drive, fast and precise clamping stroke.

07. Robot sucked out barrier stack, saving labor costs, reduce labor intensity.

08. Using quick die change equipment, pneumatic clamping.

II,Technical parameters

| Parameter | MTC 400(mode No.) | |

| Max. cutting area(mm2) | 400 × 760 | |

| Available sheet thickness (mm) | 0.3-1.5 | |

| Available sheet width (mm) | 500-800 | |

| Max. cutting force (ton) | 45 | |

| Upper mould stroke(mm) | 80 | |

| Under mold stroke (mm) | 110 | |

| Max.height of product (mm) | 70 | |

| Max.depth of product (mm) | 100 | |

| Capacity (Cycle/min) | 30 | |

| Gas source (outlay) | Air supply(m3/min) | ≥ 3 |

| Pressure(MPa) | 0.8 | |

| Power supply | three-phase four-wire 380V / 220V 50Hz | |

| Motor power(Kw) | 19 | |

| Max. power of whole machine(Kw) | 21 | |

| Dimensions (L × W × H) (mm) | 4500 × 3100 × 2900 (including motor height) | |

| Total Weight (Kgs) | 5500 | |

III,Technical configuration

| Programmable Logic Controller (PLC) | Taiwan Delta |

| 10.4 inches color touch screen | Taiwan Delta |

| Sheet feeding servo motor (1.0kw) | Taiwan Delta |

| Up mold servo motor (5.5kw) | Taiwan Delta |

| Down mold servo motor (4.5kw) | Taiwan Delta |

| AC contactor | Germany Siemens |

| Thermal relay | Germany Siemens |

| Intermediate relay | Germany Weidmuller |

| pneumatic components | Japan SMC |

| Cylinder | China |

IV,Sample Pictures

VII,Certifications

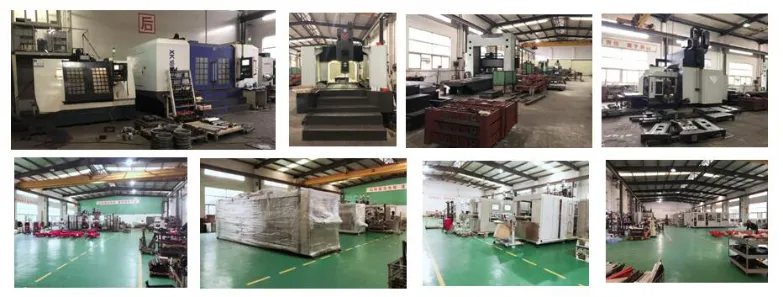

VIII,Workshop Pictures

X,Package

XI,Exhibition

The use of this product means saving time and labor costs. Thanks to its high efficiency, it can quickly finish tasks that people can not do. With a full servo drive, it has a reduced clamping force, ensuring the fast and precise clamping work.

This product has revolutionized the methods of production and has increased productivity, production, and income, thereby leading to rapid economic growth. With a full servo drive, it has a reduced clamping force, ensuring the fast and precise clamping work.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Quick Links

Products

Contact Us

Tel: +86-754-88228822

Fax: +86-754-88584033

E-mail: mx1@stmengxing.cn

Address: Block 11, Jinyuan Industrial District, Chaoshan Rd. West, Shantou, Guangdong China

E-mail: mx1@stmengxing.cn

Address: Block 11, Jinyuan Industrial District, Chaoshan Rd. West, Shantou, Guangdong China