You don't know the vacuum forming machine

by:Mengxing

2020-12-29

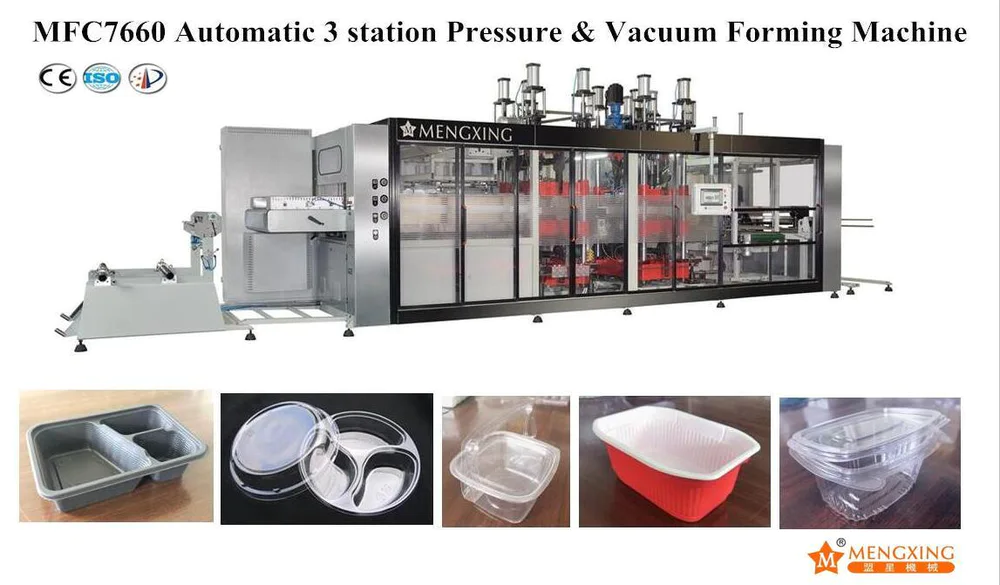

Vacuum forming machine,

Also called thermoplastic molding machine)

Is to heat the plasticizing of PVC, PE, PP, PET, HIPS, thermoplastic plastic coil made into various shapes of absorption senior decoration box, box packing machine and other products.

Using vacuum suction vacuum pump, PVC, PET, thermal plasticity after heating softening plastic sheet after vacuum forming mould into various shapes of vacuum hood, vacuum forming trays, blister, etc.

Vacuum forming technology of plastic (

Board)

Material thermal processing technology, is one of the plastic secondary processing of industrial technology.

It is different from injection molding, extrusion, such as a process, not for plastic resin particles heated moulding or with a mouth mold with cross section continuous forming;

Also does not use the machine tools, cutting tools and other mechanical processing method, will be part of the plastic material cutting down and obtain the need to shape, size, but with plastic sheet (

Board)

Material, carries on the heating, the use of mould, vacuum or pressure (

Board)

Material deformation, meet the requirements of shapes and sizes and with matching process, realize the application purpose.

Vacuum forming equipment including clamping system, heating system, vacuum and compressed air system and thermoforming of commonly used plastic molding and so on several parts performance according to the thermal behavior of plastic, can be divided into two categories, thermoplastic and thermosetting plastic.

Used in hot forming material belongs to thermoplastic materials.

Used in hot forming of single layer or multi-layer composite plastic sheet (

Board)

Material must meet the following performance 1:2: plastic memory hot stretching 3: heat intensity 4: a PVC thermoforming commonly used plastic molding temperature (

Characteristic is, less impurity content taught, transparency is good, price is the bottom, with good dielectric properties, flame retardancy and self-extinguishing)

2 PP (

Source is abundant, cheap, excellent performance, widely used.

1, the density is small,

PP colourless, odourless, tasteless, non-toxic, combustible, appearance for white density of 0.

90-0.

91g/㎝3.

)

2, good mechanical properties of PP rigidity, exceptionally good extensibility, good stress cracking resistance 3, heat resistant performance is better 4, 5, good chemical stability performance transparency, resistance to water, water proofing property is good 6 processing molding and usability strong three PE (

Production is the largest and one of the most widely used plastic varieties, odourless, tasteless, non-toxic, combustible)

4 PS (

Plastic qualitative hard, brittle, transparent, no odor, smoke during burning, easy dyeing and processing, low hygroscopicity, dimensional stability, good electrical insulation and heat insulation.

)

1, the high transparency and gloss, coloration, health good performance 3, 4 excellent dielectric properties, forming deficiency excellent performance: 1, crisp 2, poor heat resistance 3, moistureproof, poor resistance oxygen into five ABS (

Don't transparent, non-toxic, tasteless)

Six PET (

Colourless, odourless, tasteless, non-toxic, good transparency, excellent mechanical strength, wear resistance and electric insulation performance, good creep resistance, rigidity and intensity.

Excellent health let it can direct contact with food)

The basic ways of thermoforming plastic thermoforming method are many, according to the molding mould pressing and differential pressure power can be divided into two categories.

According to the forming mould, can be divided into ChanYang mode, single cavity die, to die, no mould and so on several methods of moulding, also known as mechanical stretch forming, is in the form of single mode or to die, with the help of plus mechanical pressure or weight, plastic sheets with molding into various parts of the molding method.

Male mold refers to the shape of the mould is convex, cavity die refers to die of the concave shape, mold molding products only one side, the other side when it is exposed to the air, it is different from a forming process and forming.

This method can be suitable for basic all thermoplastics.

To learn more about vacuum molding machine related information can be used to direct access to the web site:.

Custom message