Introduces a thick piece of vacuum molding machine working principle, the service life of the bumper

by:Mengxing

2020-07-18

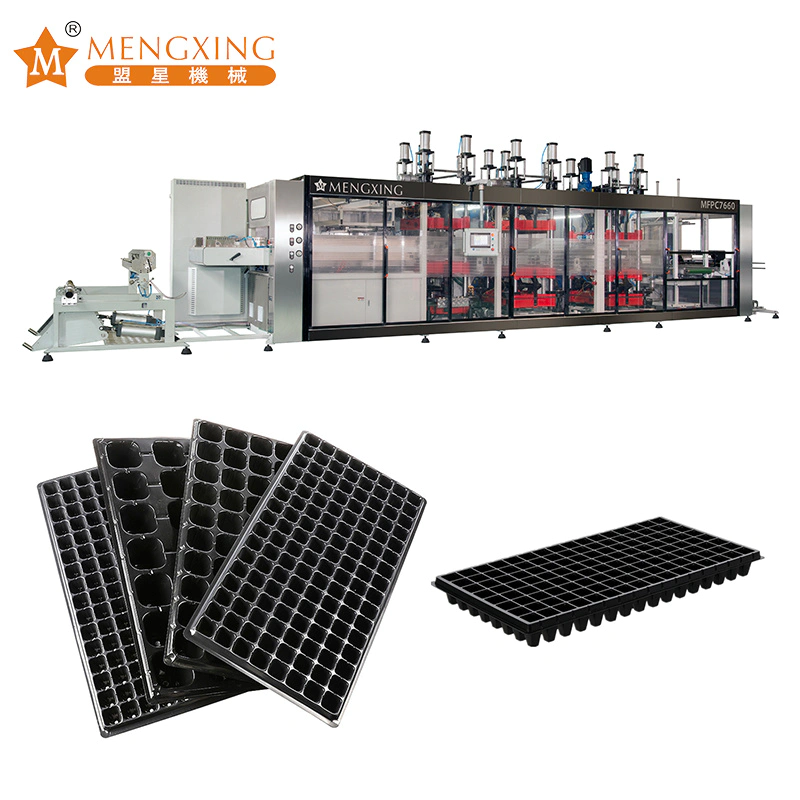

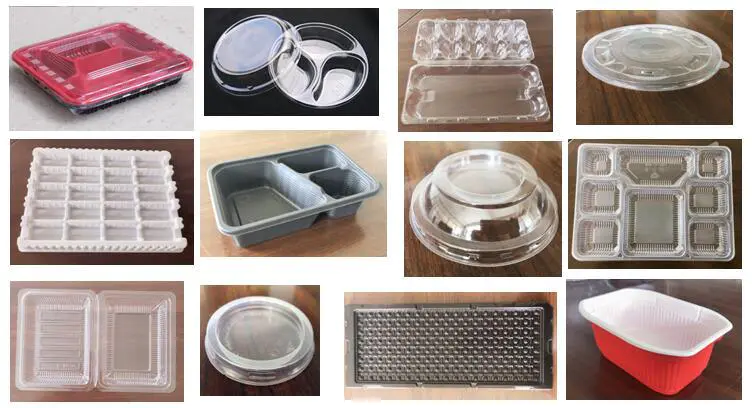

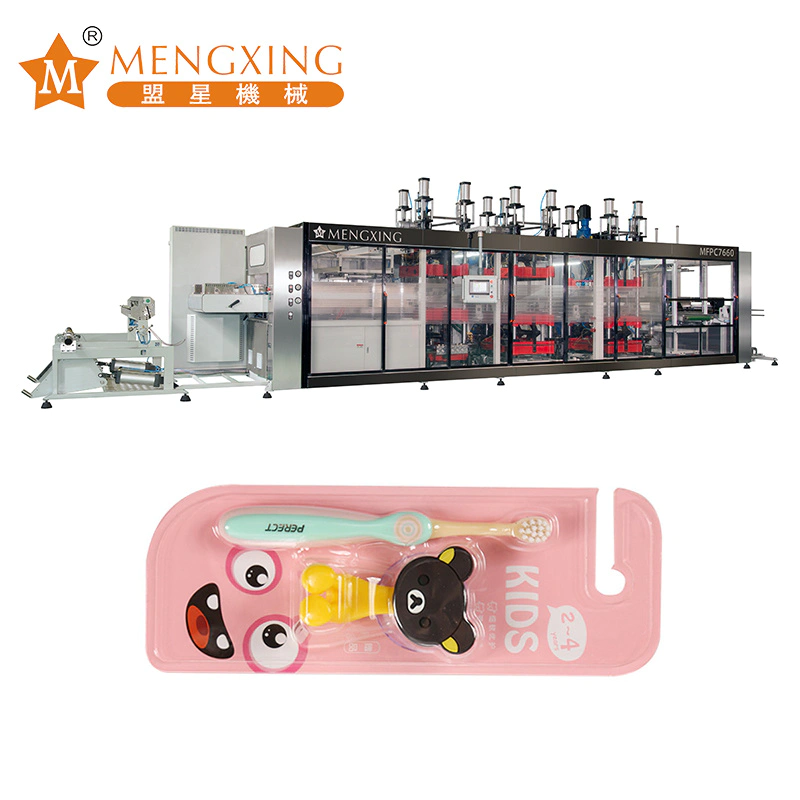

Thick slices vacuum forming machine is the plastic sheet as raw material, through the vacuum plastic molding process for making vacuum forming plastic parts of key process equipment, it by thermoplastic plastic sheet as raw material, through the oven heated to a softening temperature, and then through the plastic sheet and vacuum forming mould between the vacuum negative pressure effect, make in the state of the thermoplastic plastic plate adsorption in the vacuum forming mold cooling molding again on the working plane.

has thick slices, the working principle of vacuum molding machine equipment

thick slices vacuum forming machine principle is as follows: thick slices blister like chip blister principle, is to locate a good plank through oven heated to softening state, the blister mould with form around confined Spaces and sucking air in the cavity moment, this plate in the mold surface, cooling stereotypes

and the technological process of the obtained products.

vacuum forming is a process of circulation, each cycle mainly includes: feeding & ndash; Heating softening & ndash; Blow pre-drawn & ndash; Blister & ndash; After heating & ndash; Demoulding to take the back analysis. After take out the plastic sheet placed (again Can be received or automatic) For the next cycle.

today, a thick piece of suction SuChang manager zheng to find us, he needs to buy a car bumper vacuum forming machine. Zheng during preliminary communication manager told us that he has two factory in guangdong a company to produce large vacuum forming machine, but after less than 5 years of use, found that the device did not bring the desired results, but there has been a recent trend of scrap. The service life of the vacuum forming machine exactly how long?

the industry knows, the life of the car bumper vacuum molding machine are depends on vacuum forming machine itself configuration and assembly level.

1) The electrical appliances generally choose the Japanese and European ( Such as: omron, tight control, mitsubishi, Siemens) ;

2) Is generally in Europe (aerodynamic configuration? For example: nuo crown, festo, etc. ) Probably has more than 10 years, but ultimately depends on gas source, the bumper vacuum forming machine is commonly used piston air compressor, screw air compressor, suggest it is best to use screw air compressor, which prolongs the life of the electromagnetic valve, cylinder, etc.

3) Hot bricks can choose imported ( Such as: Germany) Life is up to 15 - commonly Twenty years is no problem;

4) As for rail aluminum alloy outsourcing stainless steel are durable lot;

5) Hot stove is made of stainless steel are durable the will of some, but the skeleton must be prepared to some, otherwise the stainless steel heating or there will be some deformation.

6) The bumper vacuum molding machine vacuum pump adopts Germany's three major brands ( Becker, the clarks, baker) Generally, as long as according to the instruction manual for maintenance can reach 15 years or so, but mainly to see if the customer is willing to spend so much money to maintain; Generally see ACF vacuum molding machine on the market, basically can reach more than 10 years, life but be sure to maintain good.

in this paper, source of WWW. xldy168。 Com vacuum forming machine

has thick slices, the working principle of vacuum molding machine equipment

thick slices vacuum forming machine principle is as follows: thick slices blister like chip blister principle, is to locate a good plank through oven heated to softening state, the blister mould with form around confined Spaces and sucking air in the cavity moment, this plate in the mold surface, cooling stereotypes

and the technological process of the obtained products.

vacuum forming is a process of circulation, each cycle mainly includes: feeding & ndash; Heating softening & ndash; Blow pre-drawn & ndash; Blister & ndash; After heating & ndash; Demoulding to take the back analysis. After take out the plastic sheet placed (again Can be received or automatic) For the next cycle.

today, a thick piece of suction SuChang manager zheng to find us, he needs to buy a car bumper vacuum forming machine. Zheng during preliminary communication manager told us that he has two factory in guangdong a company to produce large vacuum forming machine, but after less than 5 years of use, found that the device did not bring the desired results, but there has been a recent trend of scrap. The service life of the vacuum forming machine exactly how long?

the industry knows, the life of the car bumper vacuum molding machine are depends on vacuum forming machine itself configuration and assembly level.

1) The electrical appliances generally choose the Japanese and European ( Such as: omron, tight control, mitsubishi, Siemens) ;

2) Is generally in Europe (aerodynamic configuration? For example: nuo crown, festo, etc. ) Probably has more than 10 years, but ultimately depends on gas source, the bumper vacuum forming machine is commonly used piston air compressor, screw air compressor, suggest it is best to use screw air compressor, which prolongs the life of the electromagnetic valve, cylinder, etc.

3) Hot bricks can choose imported ( Such as: Germany) Life is up to 15 - commonly Twenty years is no problem;

4) As for rail aluminum alloy outsourcing stainless steel are durable lot;

5) Hot stove is made of stainless steel are durable the will of some, but the skeleton must be prepared to some, otherwise the stainless steel heating or there will be some deformation.

6) The bumper vacuum molding machine vacuum pump adopts Germany's three major brands ( Becker, the clarks, baker) Generally, as long as according to the instruction manual for maintenance can reach 15 years or so, but mainly to see if the customer is willing to spend so much money to maintain; Generally see ACF vacuum molding machine on the market, basically can reach more than 10 years, life but be sure to maintain good.

in this paper, source of WWW. xldy168。 Com vacuum forming machine

Custom message