Concavo-convex nc heterotypic is negative pressure vacuum forming machine

by:Mengxing

2020-07-12

Concavo-convex CNC is pressure machine can produce the surface effect is more ideal Gao Liangguang plank, Gao Liangguang artifacts to keep the brightness of the PVC membrane surface, to prevent the loss of light (

Appear orange peel phenomenon)

Must to control the temperature within a 91 - degree on the surface of the PVC film, once more than the temperature, the PVC membrane will natural light.

But at such a low temperature, PVC film has not been fully softened, cannot do vacuum forming machine, blister, requires the equipment is at the top of the PVC film a larger pressure, will be half a softening of PVC membrane pressure molding.

But because the heat from the above, will result in artifacts as the temperature is low.

Under heating are added later can promote the workpiece by the temperature of the workbench on the PVC membrane softening effect so as to achieve the perfect on.

At the same time due to the vacuum suction plastic for thermal activation glue, need to activated by heat stick relay, the current domestic use glue generally have 60 degrees (

One-component)

And 80 degrees (

A two-component)

2.

To ensure quality, it is recommended to use two-component glue to make several 80 artifacts, so the temperature of the workpiece closed side must not be too low.

So the temperature range between 80 degrees - 91 degrees.

The stage work heating can help to complete.

(

In view of the above reasons, if want to make the surface effect is perfect Gao Liangguang artifacts, is given priority to with flat, simple shapes.

)

Scope: 1, specular blister ambry door plank.

2, the common wood grain, monochromatic blister ambry door plank single stick of wood real wood compound door core board ambry door plank.

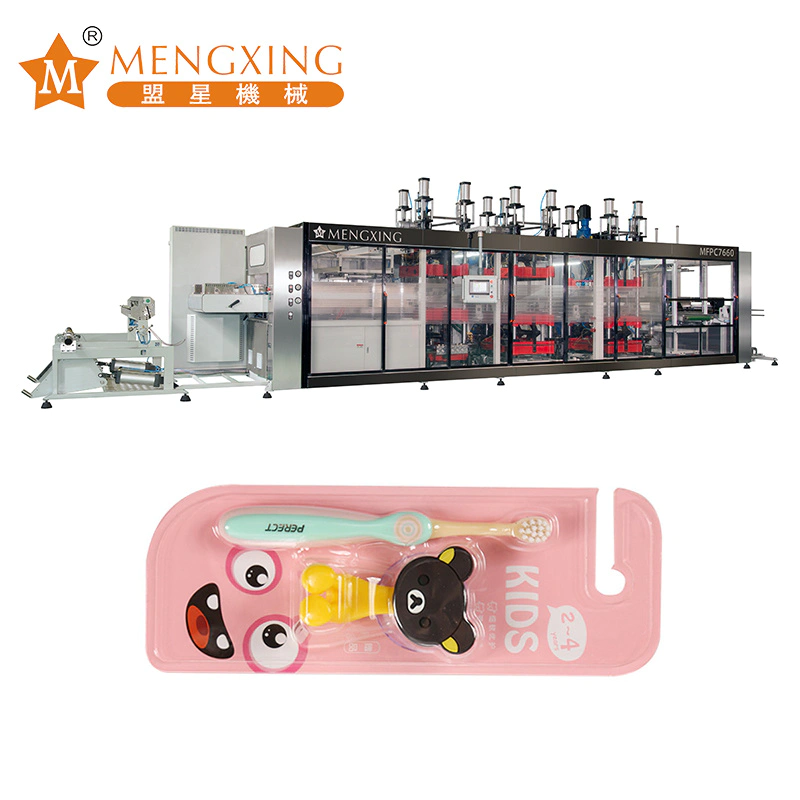

Function is introduced: can undertake all kinds of high-grade PVC, thermal transfer and veneer surface decoration.

Firm bonding of the machining of all kinds of PVC artifacts, not rebound become warped edge.

Groove lines clearly in place.

Equipment characteristics: 1, equipment rack using 6 the whole steel plate processing, no welding deformation.

2, workbench walking in and out of the system using my company's patented technology, cooperate with inverter control, a slow start, gradually accelerated, high speed, low speed stop mode.

Fundamentally put an end to the displacement of workpiece.

3, the operating system USES Taiwan in PLC programmable controller, touch screen man-machine interface, easy to control, advanced technology, high degree of automation.

4, using German technology, the domestic production assembly direct connect vacuum pump.

5, electrical system contactor used the French schneider, 0910, 2510.

Intermediate relay using Japanese omron MY2NG/MY4NG, Taiwan in DVP -

32ESO。

Other appliances in domestic components.

6, the host hydraulic system adopt Taiwan system, motor and oil pump use of Taiwan, Pepsi, principle of hydraulic system for plate instrumentation, international advanced structure, low failure rate, large flow rate, pressure quickly (

Pressure time for about 5 seconds, the traditional superposition valve pressure for 15 to 20 seconds)

。

Effectively improve the production efficiency.

Custom message