阿发, II automatic coating machine is introduced

by:Mengxing

2020-04-26

A, AFA -

II automatic coating machine use: due to the speed of the main factors influencing the coating has a coating and the coating on pressure, etc. , thus coating by artificial besmear often appear inconsistent, especially the differences between people is bigger, it's brought difficulties to comparing test results between model.

Our automatic coating machine is to make the operator to easily on the different substrate coated out accurate wet film and elaborate design, greatly improve the reproducibility of the coating.

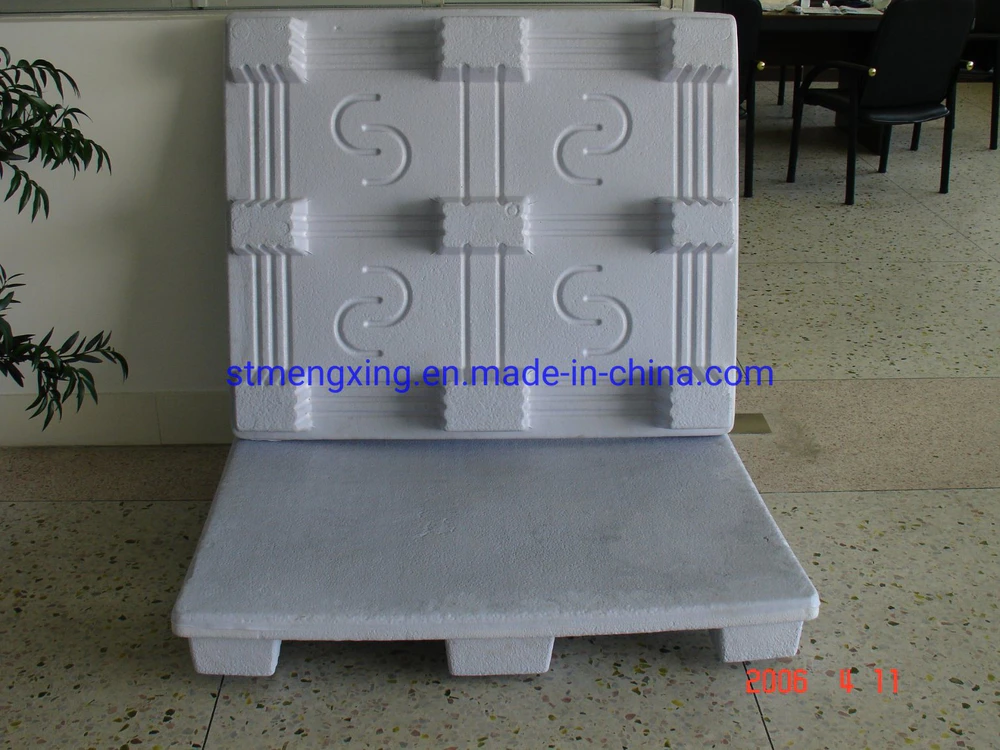

Second, the AFA -

II automatic coating machine main parameters: 1, the coating base size: 400 mm * 280 mm (

Length * width)

2, can be vacuum size: 300 mm * 210 mm (

Length * width)

3, can be coated length: 230 mm or 285 mm, the coating speed: 0 ~ 10 cm/s CVT, total power: 350 w, power supply: 220 v, 50 hz 7, appearance size: 705 mm * 505 mm * 270 mm (

Length * width * height)

8, weight: 65 kg (3, AFA -

II automatic coating machine equipment introduction: 1, this equipment adopts stepless variable speed motor, precise control coating rate.

2, used rail push wet film preparation, preparation of apparatus for wet film appearance size without special requirements.

3, using the built-in vacuum pump, convenient the carrying and handling equipment.

4, placed in the coating of the bottom of the left edge of the stainless steel waste collection plate, collecting redundant paint, to ensure that the device itself and the surrounding area clean.

Fourth, AFA -

II automatic coating machine use instructions: 1, the connected power supply.

2, to be coated substrate (

Such as: black and white paper)

Flat on coated base, open the vacuum pump switch to 'adsorption' position, at this point, the coating and substrate was adsorbed on the coated base.

(

Note: when stay less than can be vacuum coating substrate size size, application or other paper with transparent tape to cover the excess vacuum holes, in order to avoid to be coated substrate adsorption unstable, resulting in coating failure)

。

3, the horizontal push rod placed in coating base on both sides of the fixed link.

4, select the appropriate coating length, press the 'reset' button, make the horizontal push rod to the original position of the coating.

5, the wet film preparation, placed in the front of the lateral push rod.

6, select the appropriate coating speed.

7, directly in front of the wet film preparation device placed the right amount of coating.

8, press the 'start' button, coating.

9, after being coated stop, the remaining coating blew into the collecting plate.

10, close vacuum pump, remove the good model, for the next operation.

Five, the AFA -

II automatic coating machine to note: 1, in the process of equipment operation can't adjust the knob of coated length, otherwise there will be a great boot slider not action again, once this happens, you can push the slider in the end, to boot, failure can be removed.

2, coated base should be kept clean, there shall be no sundries clinging, lest affect the flatness of coating base, which affect the next coating;

If accidentally will paint dripping on the coated base, should be timely clean.

3, regularly check the oil cup of oil, if discover the oil level is not enough, should add lubricating oil in time, to guide rail lubrication.

4, this equipment after each use and application of dust cover to cover, in order to avoid dust fall into the vacuum holes, and in the vacuum pump, affect the service life.

5, this equipment after each use, should be timely cleaning waste collection plate.

Custom message