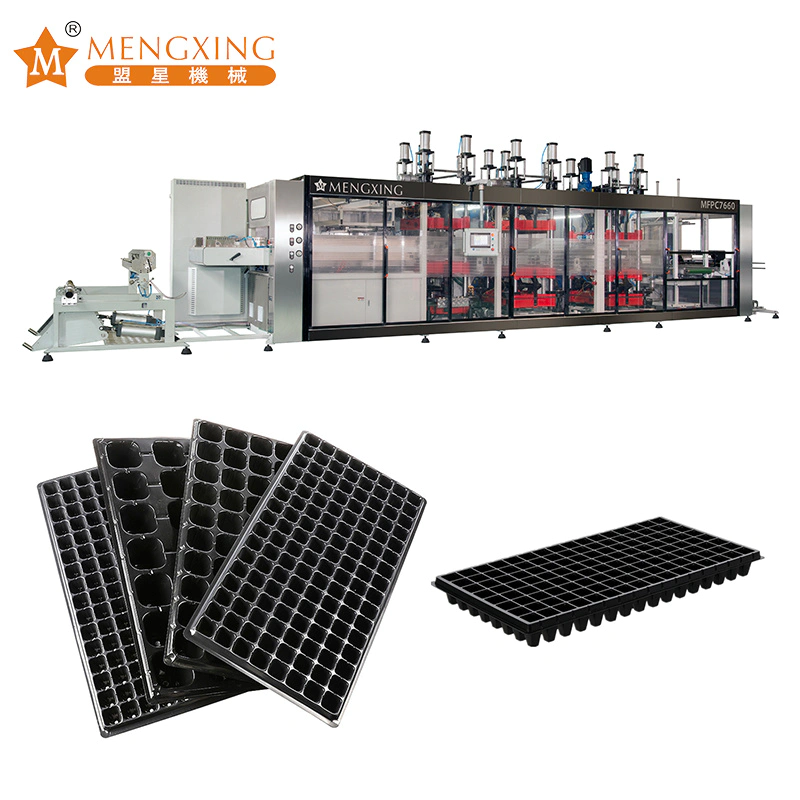

- automatic vacuum plastic molding parameters Union star packaging machinery

by:Mengxing

2020-06-19

Polyester sheet is a very good comprehensive performance of materials, high strength, good transparency, after processing also easy and many other advantages, is mainly used in automatic vacuum molding machine blister blister in production.

Due to high strength, the thickness of the same product, it can better protect, significantly better than the PVC sheet, if the same strength to compare, usable thinner polyester sheet, so, although the price of pet sheet weight is higher, but the actual cost is not big, more major is polyester sheet of transparent crystal increases the packaging effect, make the packaging on a higher level.

Again it is non-toxic, odourless, tasteless, conform to the hygiene requirements of food packaging, it has no PVC sheet burning reason when secondary environmental pollution problems, the PVC sheet to ban the use of on the disposable packing cases, can conform to the packaging application has higher strength sheet, is undoubtedly the pet sheet.

Polyester sheet processing of blister packaging products, convenient and common automatic vacuum molding machine can be normal processing, efficiency and PVC sheet, so the original production of PVC sheet blister products equipment without any modification.

Immediately after extrusion molding, material surface texture.

When the extrudate temperature is higher, embossed roll on the surface of embossing.

When material on the thermoforming machine heating, indentation on the surface of the reply after the cooling, such as loss on the surface of the texture effect becomes smooth.

Sealing layer or extrusion coating, generally use more than one production extruder, a total of extrusion method, two layers of sheet bonded or melt in slit nose just fuse when it is squeezed from the nose.

Printing vacuum forming sheet, in addition to the printing color, can use hot bonding coating and protective coating.

As vacuum forming the required printing paint, should be used with the plastic material has good compatibility of paint types, in order to ensure its good adhesion.

Flocking is a process, usually with special cat mixture to nylon fiber flocking to the material surface.

Flocking automatic vacuum molding machine tray because of thermoforming stretching, can make the flocking separation from the material surface.

Flocking side in a vacuum, vacuum forming without contact with the mould surface.

Under the condition of high vacuum metallization process, aluminum evaporation to one side of the sheet surface.

The following materials can be metallized treatment: polystyrene (

PS)

, polyester (

PET)

, PVC (

PVC)

And polypropylene (

PP)

And so on.

Coating is not strong.

Metal processing of materials can be used in hot forming, but when the tensile aluminum plating layer thinning, and will therefore not transparent.

Compression layer of the galvanized sheet become a reflection piece, can use molding vacuum forming, the extended its just a bit is limited.

Electroplating and metallization of vacuum forming materials, the plating side reflection radiation heater thermal radiation, therefore can only go to the side with the heating without metallization.

If it is in full automatic vacuum molding machine after vacuum forming plating parts, special electroplating materials should be used.

Post-processing: punching and cutting performance is excellent, but impact pressure is 60% higher than PVC.

On the other hand, cutting time is quite short.

Heating of the die cutter cutting length can be increased, at 100 ℃ increased by 11%, at 130 ℃ increased by 25%, a 40% increase in 160 ℃.

The APET cover shell heat sealing on the plate temperature is 190 ~ 240 ℃, sealing time is 1.

2 ~ 2.

5s;

Coated heat sealing paint on board is very important, APET sheet film heat sealing is more difficult than composite membrane.

APET film of APET film (

One component packaging materials)

Heat sealing in the temperature range from 160 ~ 240 ℃, heat sealing time 0.

7 ~ 2.

Between 5 s implementation.

Au XingQuan automatic vacuum molding machine: /

Custom message