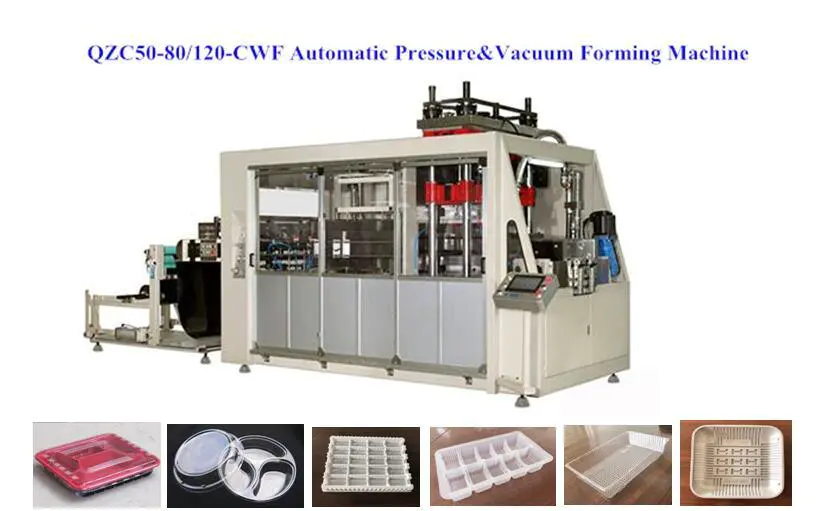

Automatic vacuum molding machine - five maintenance points Union star packaging machinery

by:Mengxing

2020-06-17

1, regular check molding machine air compression equipment, automatic vacuum molding machine of pneumatic system is composed of suction machines in itself bring some compressor, workshop director path sets, storage tanks, valves and other combination.

Now most of the compressor is equipped with forced ventilation device for air compressor, but channeling air pollutants in sedimentary around forced ventilation device, may make the valve plug, even damage the compressor.

Therefore, must be maintained regularly forced ventilation device, eliminate pollutants around the forced ventilation device.

2, regular maintenance of rust on the cooling equipment and the scale will limit the cooling fluid flow in the cooling system, reduce the heat dissipation effect, lead to material overheating, even cause the failure of the molding.

Melt cooling were also can form acid, tank corrosion of metal parts, damage to the tank, leakage.

Regular use of strong efficient cleaner water tank, remove the rust and scale, not only can guarantee the machine to work properly, and extension of water tank's whole life.

3, check the suction molding machine control equipment on a regular basis for microcomputer instruments, meters, pipe, valves, various parameters and move to look at it.

4, regular cleaning vacuum system fully automatic vacuum molding machine of the vacuum system consists of vacuum pumps, storage tanks, valves, piping and vacuum gauge, etc, used in vacuum forming type vacuum pump alone.

Gas-holder is generally with sheet steel welded cylindrical box, bottom is elliptical.

The capacity of the storage tank should be at least half than maximum molding chamber capacity.

Small amount of suspended in the oil, when large amount of precipitation from oil, blocking filter and oil hole, vacuum pump lubrication hard, causing wear and tear.

In addition, when the oil in the high temperature oxidation generates film and carbon bonded on the piston, make vacuum pump oil consumption increases, power drop, serious lag piston ring and cylinder.

Therefore, regular use of lubrication system efficient fast cleaner crankcase, maintain clean inside the vacuum pump.

5, maintain good suction machines in the stability of heating thermoplastic plastic sheets regularly check whether the effectiveness of the fever is normal, heating temperature is balanced if appear strange in a timely manner to change so that equipment forming neat.

Au XingQuan automatic vacuum molding machine /

Custom message