What is vacuum forming excuse me?

by:Mengxing

2020-12-29

Vacuum forming, a kind of plastic processing technology, the main principle is to flat heat soft plastic plate material, adopts the vacuum adsorption on surface of mould, cooling after forming, is widely used in plastic packaging, lighting, advertising, decoration and other industries.

Use classification of vacuum forming packaging: the vacuum forming process to produce plastic products, and the corresponding equipment to the floorboard of the packaging products.

Vacuum forming packaging products include: bubble shell, tray, vacuum forming box, synonyms are: vacuum enclosures, blister, etc.

Main advantages are the main benefits of vacuum forming packaging, save raw and auxiliary materials, light weight, convenient transportation and good seal performance, in line with the requirements of environmental protection green packaging;

Packing can be any abnormity products, without additional buffer materials;

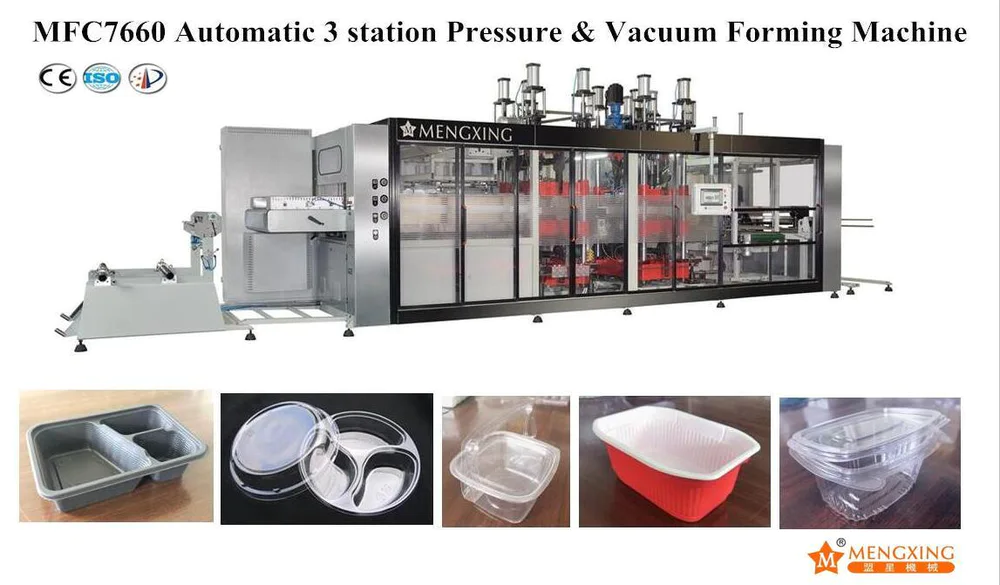

Be transparent packaging products, beautiful appearance, easy to sales, and is suitable for mechanization and automation of packaging, is advantageous for the modern management, save manpower, improve the efficiency of production equipment vacuum forming packaging equipment mainly includes: the vacuum forming machine, punching machine, sealing machine, high frequency machine, folding machine.

Encapsulated form the packing of the products can be divided into: card, suction card, double blister, blister, folded in half for blister, blister blister packaging such as thirty percent thirty percent and thirty percent for blister packing is blister fold into three sides (

Top, bottom, back)

, forming a bottom edge, so that products can stand on the plane.

Its characteristic is can not use sealing side of high frequency technology, but the clasp on the position in the blister must do to connect to the blister, when necessary, can also play on the stitching needle, PET plate can be used in material selection, and achieve the purpose of environmental protection material, the packing of the products is suitable for large diameter.

Some problems that should be paid attention to: 1.

Because of no sealing side of high frequency machine, cutting bed is needed in the edge of the high quality cutting is complete;

2.

Buckle a looseness wants moderate.

Molding process hot molding process process roughly: plastic sheet -

—

Cutting -

—

Sheet fixed -

—

Heat -

—

Shape -

—

Demoulding -

—

To material side -

—

The finished product.

Custom message