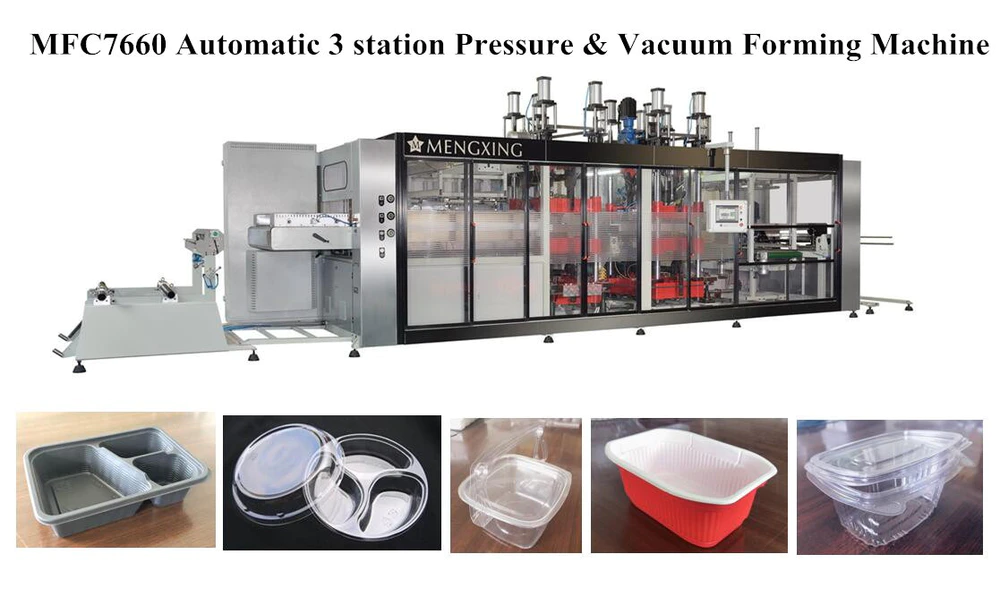

Introduction - thermoforming machine Union star packaging machinery

by:Mengxing

2020-06-17

Used in the thermoplastic plastic sheet molding machine there are basically two forms: sheet feeding and single feed.

Sheet feeding type heat molding machine with drum shape sheet feeding, or directly with the sheet extruder into running water production line.

Monolithic feeding type hot forming machine is named after the deep into the pre cut piece of material.

Continuous sheet feeding type is very popular hot molding machine, can produce high quality products at high speed, and according to the standard supply, the most popular 60 & times;

90报;

90125报;

106 cm specifications, etc.

This kind of thermoforming machine design often has a length of 3 ~ 4 times the longest mold size of the heating furnace.

Most of the heating furnace is electric heating, and install in can be away from the sheet transfer system frame.

Oven with C type frame and door type two main forms.

Thermoforming system driven by hydraulic or mechanical.

Monolithic thermoforming machine feeding type can be divided into two categories, rotary and shuttle.

Rotary thermoforming machine is often used in a large number of products production.

Common standard thermoforming machine for three station, station rotary degrees for 120 & deg;

;

Also have 4 Labour thermoforming machine, which add a heating station.

Shuttle thermoforming machine has a forming station, sheet clip on the clamp frame, and then over the furnace reciprocating movement.

Also designed two station and a double location thermoforming machine composed of oven.

This kind of thermoforming machine processing has a wide adaptability.

Custom message