Automatic blister forming machine principle and control - Union star packaging machinery

by:Mengxing

2020-06-17

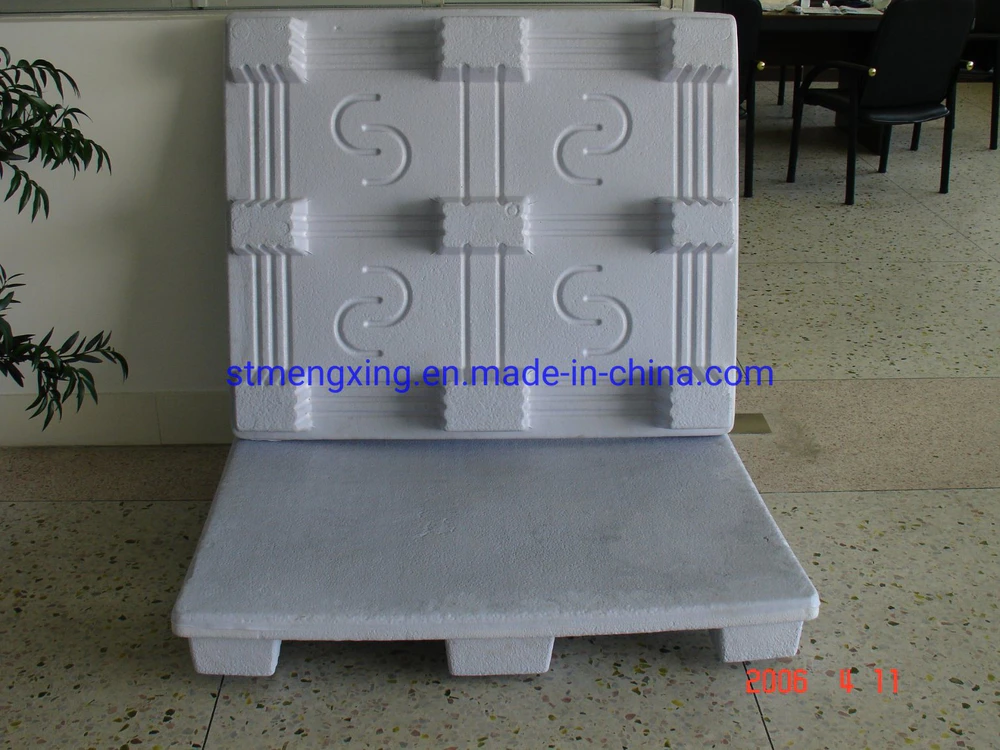

Automatic vacuum molding machine working principle is to use blister forming machine principle.

Vacuum forming process is a way of hot forming.

Using the thermal contraction principle, the use of thermoplastic materials, produce products have open shell, only shape is packaging material.

Automatic vacuum molding machine manufacturers resolution for blister, will according to the customer request a plaster mold, take a sample for customer confirmation.

After factory redo of copper, because copper is extremely easy conduction temperature, and then can start production.

Manufacturers will be customer demand, good resolution, the thickness of the blister to start producing products.

Volume will amplify the blister before vacuum molding machine, using thermal heating machine, arriving at certain temperature, the will blister paper to pressure on copper, blister paper will form and because of the heat of the same shape of copper products.

On the copper will henceforth have its official affirmation of grain, the final product will also have the same grain.

After cutting, decorate, make products that meet the requirements.

Automatic vacuum molding machine molding way on vacuum force make the tensile deformation.

Because of this force is easy to implement and control, so the vacuum forming in the earliest time, so far is also the most widely used a way of thermoforming.

Automatic suction molding machine

Custom message